Unit heaters: wall- and ceiling-mounted units

Benefits

- Heat exchanger options for the most diverse applications

- Extensive range of accessories

- Silent sickle-blade fan with EC technology

- A wide range of models to meet every design need - “TOP” in terms of price and performance

- TOP units essentially meet the demand for cost-effective and controllable air handling.

- Neutral in colour, it is robust and strong

- Energy-saving sickle-blade axial EC fan fulfills the ErP requirements

- Single row louvre and fan guard

- Electromechanical control or KaControl system possible

- Can be integrated into KaControl networks or building automation system, such as BACnet, Modbus or LON

- Aerodynamic sickle-blade whisper-quiet cast-aluminium fan with optimised full nozzle

- The following models of fan are available:

- 1-stage, 1-phase sickle-blade whisper-quiet fan 230 V/50 Hz

- 2-stage, 3-phase sickle-blade whisper-quiet fan 400 V/50 Hz

- 2-stage, 3-phase wide-blade fan 400 V/50 Hz, explosion-proof (on request)

- 0-100% fan speed control

- EC fans

- There are four models of heat exchanger available:

- Copper/aluminium, ideal for low temperature systems

- Galvanised steel, for LPHW, LPWW and thermal oil

- Galvanised steel, for steam

- Galvanised steel, cross-counterflow

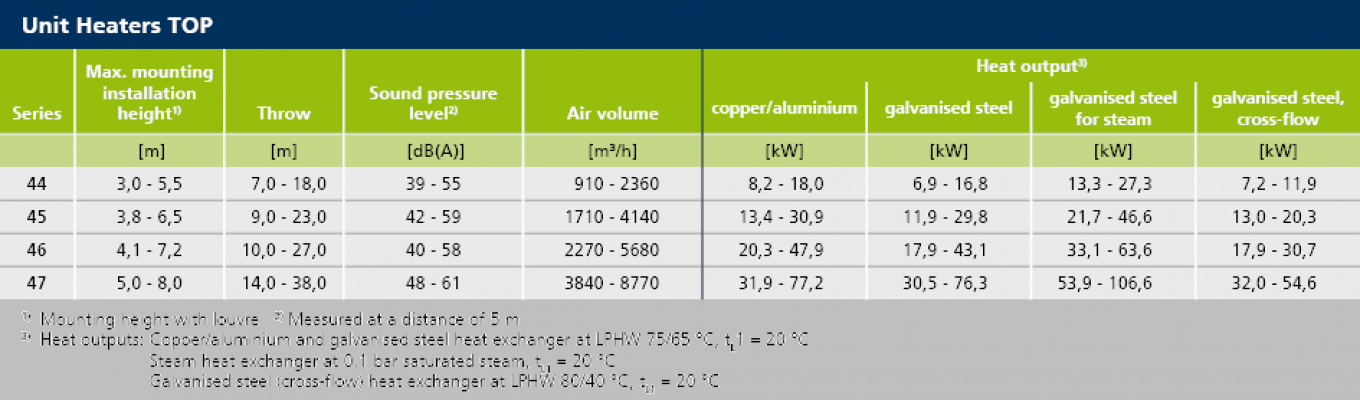

Technical details:

- Production plants, warehouses

- Builings connected to district heating systems or with wide temperature ranges

- Areas at risk of explosion

- Buildings with steam heating plants

- It is supplied complete with standard wall/ceiling brackets

- Fast delivery service: All unit heaters with copper-aluminium heat exchangers and 2-stage, 3-phase motors are available ex-stock.

- Housing self-supporting, completely made of galvanised steel metal, powdercoated on request

- Comprehensive range of modular accessories for simple adaptation to technical and structural requirements (for recirculating air or mixed air operation)

TOP unit heaters can be used for recirculating air and for mixed air operation. They are therefore ideal for the optimum decentralised heating and ventilation of production plants, warehouses and many other buildings in industry and commerce. Special heat exchangers with a low exchange capacity are available for use with low water temperatures.

TOP unit heaters can be combined with a whole range of different models of fans and heat exchangers. Single-phase and three-phase fans are available, with the 3-phase fans also being available as explosion-proof fans. All of the fans are 0-100% controllable.

TOP unit heaters can be selected with the most appropriate heat exchanger, depending on the heating medium being used and the area of use. While copper/aluminium heat exchangers can be operated cost-effectively in areas with normal air pollution, steel heat exchangers should be used anywhere that particularly durable heat exchanger are required or with steam and crossflow heat exchangers for wide temperature spreads.

Yes. If the boiler is overworked, the flow temperature drops until the hear output of the boiler and the output of the units is identical again. This frequently happens in the morning when the units are being heated-up for the first time and the entire building is switching over to day mode.